Most experts agree that to define Severe Service Valves (SSVs), they must identify the application it will be used for. These applications must be challenging to the valve’s ability to provide a minimum acceptable level of performance over a minimum acceptable duration.

Severe Service Valves can be found in non-return, isolation and control functions, although it is recognized that Severe Service Control Valves (SSCVs) do have reasonable industry agreement on what can define severe service. Severe Service Isolation Valves (SSIVs) do not have nearly as clear agreement or understanding.

Non-return (check) valves for severe service applications should be treated as control valves and sized so that their operation is consistent with the flow-rates of the process rather than the pipe size they are typically selected for.

Control valves take energy out of a piping system; isolation valves contain the energy and non-return valves delay and reduce the energy from its full effects on the isolation and control valves. All valve design functions require basic information, but those valves destined for severe service require a deeper understanding of all of the factors that affect their in-service performance.

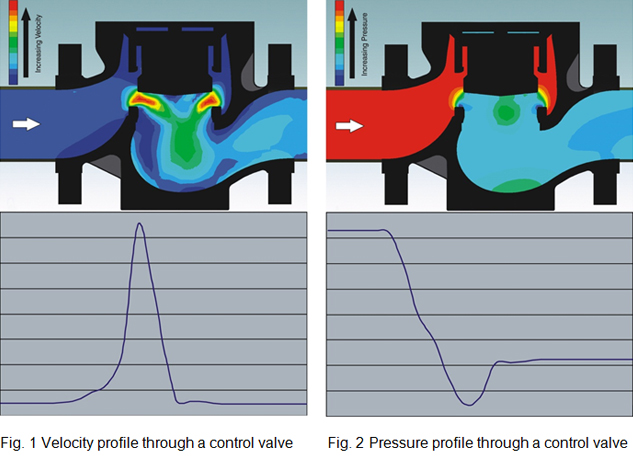

Figures 1 and 2 are a snapshot of the dynamic fluid state through a control valve showing the energy lost during the pressure drop. Figures 3 and 4 show various combinations of mechanisms that can effectively absorb that energy and protect the valve and downstream components from damage.

Leave Comment